One of the problems with modelling in 009 / H0e / H0m / H0n30 is the lack of remote controlled decoupler systems at affordable prices.

For those not wanting to exchange all their couplings for magnetic operated Greenwich etched brass couplings or Microtrains or Kadee couplers the alternatives are either the manual Peco SL-430 uncoupler or solenoid uncouplers such as the £30+ Uhlenbrock 83300 REPA (also sold under their own branding by Bemo and Conrad) and the Herkat 2703 at £15.

I did not want to use solenoid powered uncoupling ramps because, when used with light-weight rolling stock, they can be too violent, launching wagons upwards as though from Cape Canaveral.

I therefore decided to try and make my own uncoupler using an £1.50 RC servo, some 15mm aluminium channel and K&S brass square section tubing in 5/16″ and 1/8″.

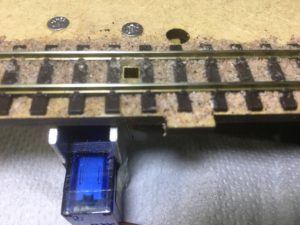

By using two sizes of square section tubing that slide inside one another I could produce a system that stayed aligned with the track.To fit the socket you just drill a 4.5mm hole between two sleepers and press fit the short larger tube into the hole, flush with the ballast. A drop of super glue on the underside of the baseboard can be used to lock the tube in place.

To make the uncoupler I soldered a 1/8″ strip of brass to the top of the 1″ long 1/8″ brass tube to form a ‘T’ shaped ‘piston’.

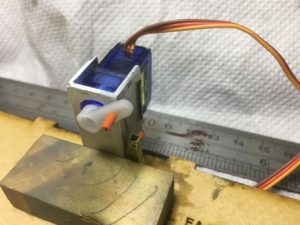

The next thing was to locate and mount the servo. For this I bought some 15mm x 15mm x 1.5mm extruded aluminium channel. The SG90 9G Micro gear servo motor is a tight fit into the channel and does not need any fastening. I drilled a 8mm diameter hole in the base of 1.5″ long section of aluminium channel so that the servo drive protruded through the back of the channel.

The channel was screwed to a wooden block that was glued under the baseboard close to the protruding 5/16″ brass guide tube.

The servo was connected to the ‘piston’ using 0.8mm spring wire bent to shape. To stop the spring wire working its way out of either the ‘piston’ or servo actuating arm, small pieces of electrical wire sheath were pushed onto the protruding spring wires and held in place with a drop of super-glue.

The brass top bar to the piston was deliberately made too narrow so that there was no chance of it bridging the back-to-back of the metal wheels. I therefore glued a small strip of Evergreen plastic ‘U’ channel over the brass to increase its width to enable it to actuate the couplers.

So there you have it, a remote-controlled uncoupling ramp for REPA/Bemo couplers for less than £5 each.

So there you have it, a remote-controlled uncoupling ramp for REPA/Bemo couplers for less than £5 each.

The next job is to program up the ESU SwitchPilot Servo unit to set the minimum and maximum throw and the speed of operation to enable a reliable, smooth, uncoupling action.

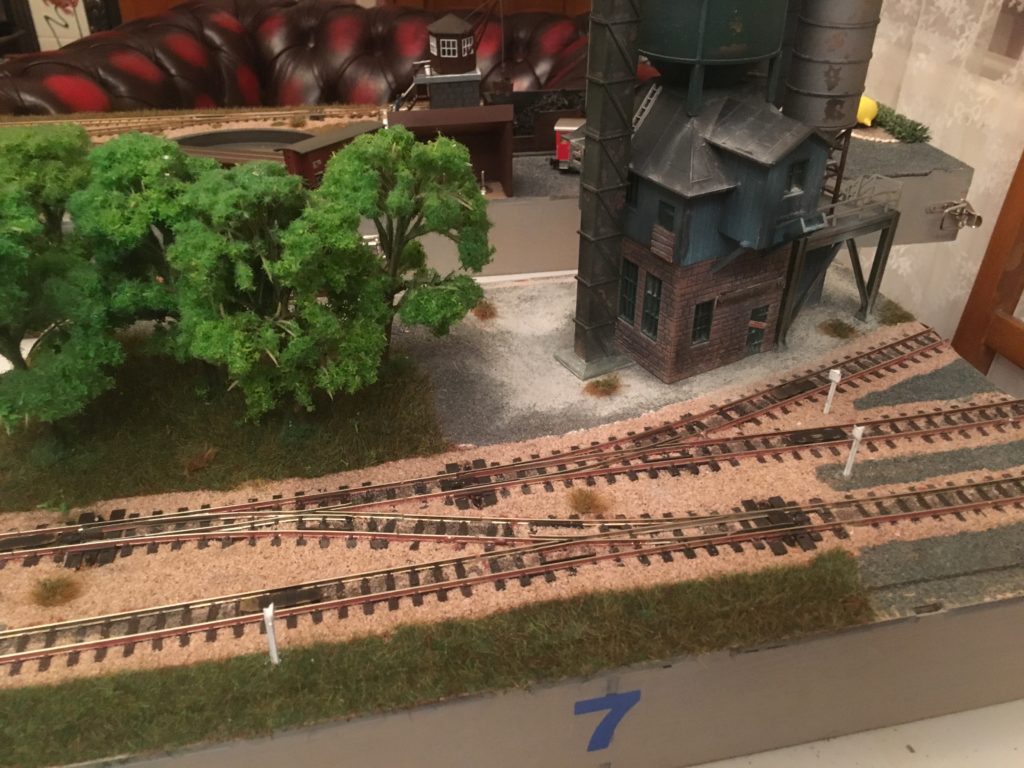

Below is a short video of the prototype in action. A small piece of transparent plastic has been glued to the ‘piston’ to increase the effective width for some rolling stock. This has been painted to blend it in with the sleepers and ballast. White posts have been placed to mark the middle of the uncouplers to aid in positioning the wagons for uncoupling.