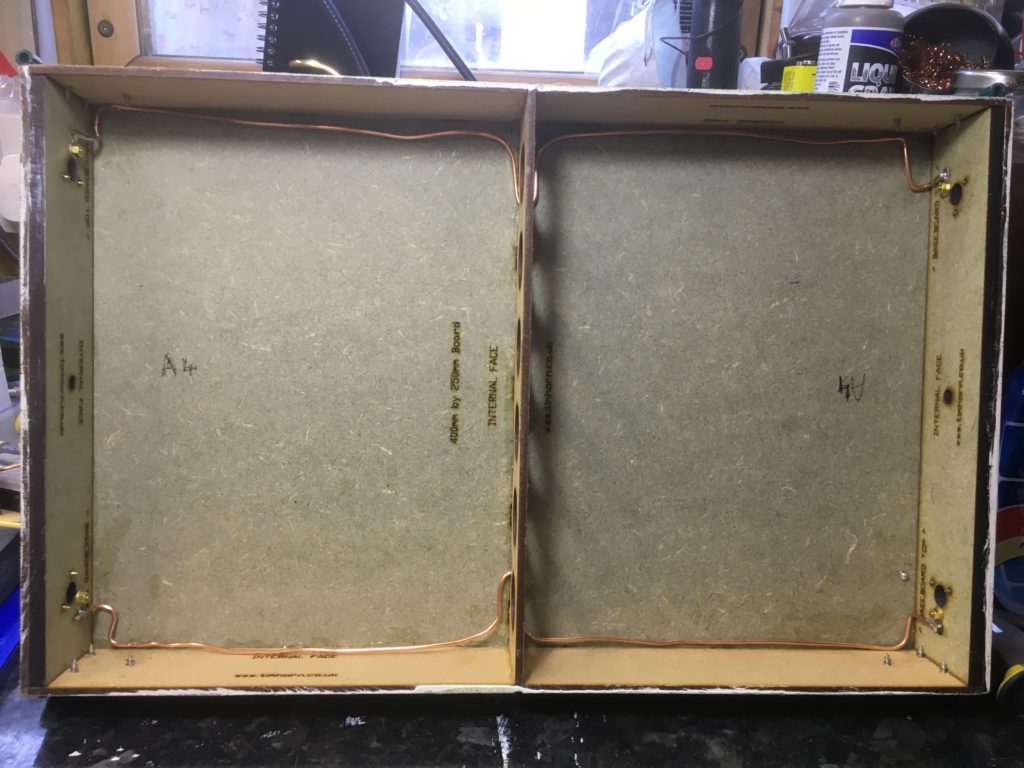

On my new layout I am again are using the brass pattern makers’ dowels that align the boards to transfer the DCC power and control signals between the boards. 2mm bare solid copper wire is used to create a power/signal busbar between the dowels.

The electrical contact between the male and female pattern maker’s dowels

is affected by the tolerances of the two parts and so, to enhance the conductivity, I designed and had etched some 0.2mm brass (and 0.2mm phosphor bronze) contact plates to fit behind the female dowel to make a positive, slightly sprung, contact on the male dowels’s pin. The etches were produced by PPD Ltd.

Experiments showed that the phosphor bronze adapters, though originally stiffer than the brass ones, deformed as expected but did not have sufficient springiness to make a repeatable reliable contact. The brass adapters, even though softer than the phosphor bronze ones, retain a small amount springiness to work as designed.

The overall resistance through the bus of the complete layout is less than 0.5 Ohms, the lowest reading than can be displayed on my digital multimeter.