Unfortunately the provider of Custom Model Decals (custom-model-decals.com) has had to retire and cease trading due to Ill Health. Andrew Jeffcock (aged 70) suffered from a small stroke last year and has now been diagnosed with a significant brain tumour. The combined effects from these conditions now make it impossible for him to continue to […]

New storage for Die Keinnamebahn’s rolling stock and its bits-n-bobs

Finally a home for all the boxes of locos, wagons, DCC controllers etc.etc. A trip to Ikea on Monday and a Hejne shelving kit later and now Die Keinnamebahn has an indexed store in my attic.

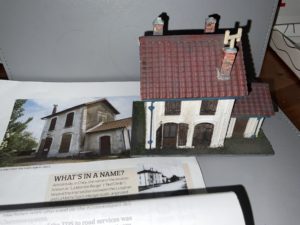

1:87 model ‘Chey’ station by Bob Dawson A.C.O.M.B Architectural Models, York

I have been extremely fortunate to have employed Bob Dawson of A.C.O.M.B Architectural Models, York to make me a 1/87 model French NG station based on ‘Chey’. Bob has done a excellent job in making a model that captures the essense of the small stations used on the French narrow gauge lines. The original plans […]

One is never enough! Collecting model trains is addictive! The perils of visiting trade stands at model shows!

As a keen HOe scale model railway builder and exhibitor of my layout “Die Keinnamebahn” my wallet is repeatedly placed under attack by the traders at these shows! It means that I now have several versions of the same model in my rolling stock. This week’s addition is the Roco Mh4 H0e locomotive with DCC […]

DCC sound just gets better and better!

I purchased an ‘as new’ second-hand Ferrotrain VL-12 H0e model diesel with the factory fitted Zimo DCC sound decoder from the 009 Society members-only sales site. The new price was four-hundred and fifty pounds but I obtained it from the 009 Society for only one hundred and fifty pounds, a real bargain. This model is […]

Servicing and storing rolling stock on Die Keinnamebahn

I have just spent 3 days working on the locos for Die Keinnamebahn. Exhibition running after a 2 year storage certainly shows up any problems with your stock. After our Cromford show I have now serviced 24 locos and recalibrated them to a scale 25mph top speed to work on a DCC track voltage of 12 […]

Die Keinnamebahn at Mount Tabor Models Show, Cromford 5/6 March 2022

I was fortunate to be invited to take Die Keinnamebahn to the Mount Tabor Models Nurnberg Spring Models Show at Cromford in Derbyshire on Saturday/Sunday 5/6th March. A small show but very satisfying to attend after more than 2 years of Covid restrictions. We were able to try out our new overhead LED lighting system […]

Die Keinnamebahn gets a new Roco Z21 DCC controller

A Happy New Year to all my readers. After much deliberation I have made the decision to move away from my home-made Raspberry Pi based DCC control system to use the Roco Z21 DCC control system. The Z21 system is easier to program and use and integrates extremely well with my iPads and iPhone and […]

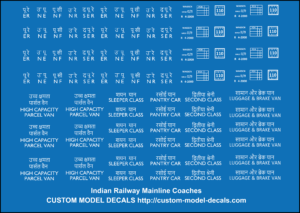

New Indian coach decals from Custom Model Decals

Custom Model Decals (https://custom-model-decals.com) have announced a new set of decals for the Indian Railway mainline coaches. These accurate Hindi-English decals could easily be used on an Indian narrow-gauge layout. The decals were developed with the invaluable help of Jeremiah Bunyan in India, his mother undertaking the Hindi translations and checking that the Hindi was […]

009 Society display their members-only models

The 009 Society, which represents narrow gauge modellers in 3.5 & 4mm/ft scales, have recently added a page to their website displaying their members-only model kits. Very reasonably priced they make nice models of narrow gauge rolling stock. https://009society.com/news/009-society-kits/ for more details

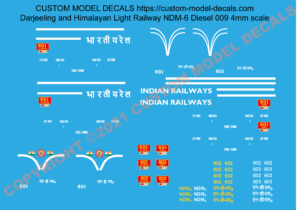

Custom Model Decals Darjeeling Himalayan Light Railway 4mm & 3.5mm scale decals

The innovative decal design business Custom Model Decals (https://custom-model-decals.com (https://custom-model-decals.com) have announced that they have developed waterslide decals for the Darjeeling Himalayan Light Railway NDM 6 diesels and their accompanying coach sets in both 009 4mm/ft 1:76 and H0e 3.5mm/ft 1:87 scales. The decals use their innovative ‘film-free’ decal technology where accurate cutting out is […]

009 Society Members’ Only Shop Now Viewable by The Public

The 009 Society have always had a sales service for its members. They have had a private, viewable by members-only on-line shop since October 2020 which enabled its members to but second hand narrow gauge rolling stock, engines and the Society’ exclusive kits and regalia. The Society’ Committee have taken the decision to now allow […]

A Happy Christmas to all and a little H0e present to myself

May I wish all of this blog’s readers a happy Christmas and a safe and better New Year and 2021. I have treated myself to this wagon by the excellent modeller Leigh Hulatt. It is a 16-wheel heavy duty well wagon based on a 1920s Austrian prototype.

New decals for Ffestiniog Welsh Pony in 7mm

The new UK producers of waterslide decals, Custom Model Decals, have designed and produced 7mm/ft scale decals to fit the Mercian Models kit for Welsh Pony. These new decals are for the recently displayed new livery for the Ffestiniog Railway’s latest restoration project. More details on these decals can be found here: https://custom-model-decals.com/decal-news/welsh-pony-decals-to-fit-7mm-ft-scale-mercian-models-kit/

A nice guide to using resistance soldering units

This is a nice video guide to using resistance soldering units from the Scalefour Society.

Custom Model Decals show readable 0.6mm high text on waterslide decals

Custom Model Decals displayed recently their latest decals which have readable text at only 0.6mm high. The use of their high-tech printer enables them to produce high-definition custom decals in as little as 7 days for clients in many scales. Currently Custom Model Decals are offering a 5% discount to members of several model societies […]

A New Custom Decal Service

A new decal production service has come online. Custom Model Decals are offering a customised decal production service for waterslide transfers. Using a state of the art white+colour printer they can produce linings down to 0.3mm in width and will Initially provide lining and also the lettering for all the Lynton & Barnstaple Railway in L&BR […]

New H0e 10 tonne hopper wagon (schotterwagen) for Die Keinnamebahn

I have recently commissioned a set of three freelance 10 tonne hopper wagons (schotterwagen) for Die Keinnamebahn. They are being scratch built by Leigh Hulatt and are nearly ready for delivery. This is one during its construction. I am proposing having the side panels selected from these test images. I will be trying to produce […]

The development of the new exhibition lighting rig for Die Keinnamebahn

I wanted to make a portable lighting rig that I could use for either my 12ft Die Keinnamebahn layout or a smaller 6ft layout. I have decided that I would use a 4m professional lighting truss which is assembled from 1m sections that can fit into my estate car. I did not want to use […]

A potentially dangerous mains powered soldering iron

I recently ordered a 60w mains-powered soldering iron with automatic solder feed via eBay from a U.K. supplier. I received the following message and a full refund. “Hi dear customer, Thank you for your purchasing. We are so sorry to tell you that because of some accident, we found that our product have some quality problem. Please […]

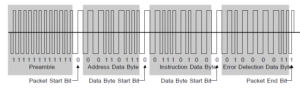

An Arduino controlled DCC layout mimic panel for Die Keinnamebahn

As my first Arduino project I chose to develop an Arduino Mega 2560 controlled layout mimic panel for my H0e “Die Keinnamebahn” exhibition layout. It just requires being connected to the DCC signals sent to the layout and is powered by either a USB connection to a computer or power source or to a 12 […]

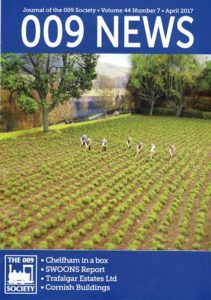

The 009 Society place their archive of the 009 News online

The 009 Society (https://009society.com) have now placed their archive of 009 News, the Society’s journal on narrow gauge modelling, online for access by its members. With nearly 20 years issues currently available this archive in PDF digital form is a history of narrow gauge railway modelling. The public can search the archive article titles but […]

An inexpensive paint shaker for model makers?

I am going to try this paint/nail varnish shaker bought inexpensively from eBay. It grips small bottles on their caps using various sized adapters. It should work nicely with the small dropper bottles I buy to store my paint mixes in and the almost identically dimensioned Vallejo acrylic paints I use.

New website for the 009 Society

I am pleased to announce that the 009 Society now have a new website at https://009society.com produced by Andrew Jeffcock of Retiarius Internet Design. Some of the new features they have on this website are: New public pages to advertise the work of the Society, its aims and to provide information on exhibitions where you […]

Appointed as the new Webmaster to the 009 Society

The official announcement has been made in the December issue of 009 News, the official journal of the 009 Society, an international society dedicated to the small scale modelling of narrow gauge railways that I have been appointed as theIr new Webmaster. I will be responsible for all the Internet-facing activities for the Society and […]

More UK Model Shops Added To Our List

We have now added another 20 UK model shops to our listing.

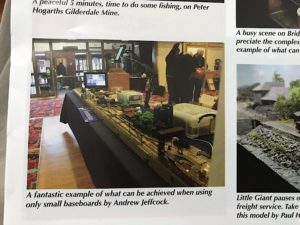

Die Keinnamebahn at Conwy 6/7 July 2019

Well, we are now back home after the North Wales N Gauge Society show at Conwy. We were made most welcome by all the society members there and we had a lovely friendly show with hardly a gremlin in sight. Die Keinnamebahn ran perfectly and only needed occasion track and wheel cleaning to be able […]

Mitigation of radio frequency interference of DCC commands induced on trackwork

I have now completely rewired the underside of the nine baseboards that comprise Die Keinnamebahn. The following tasks have been completed since our recent RF induced system failure at the Bakewell show. All power/DCC buses under the boards have been replaced with 2mm diameter solid copper wire. As many track feeds as possible have been […]

Radio Frequency Interference and a DCC disaster at an exhibition

We took our layout “Die Keinnamebahn” to the Chesterfield Model Railway Society annual show at Bakewell, Derbyshire for their weekend-long exhibition. We set up on the Friday evening and immediately had DCC control problems. Locos would start in the fiddle yard but would be jerky in operation and would ‘die’ about 1/4 of the way […]

Excellent service at a time of need!

My layout “Die Keinnamebahn” uses a Raspberry Pi interfaced to a SPROG 3 DCC controller. Whilst doing my pre-exhibition tests prior to taking the layout to Bakewell, Derbyshire for the Chesterfield Model Railway Society Exhibition this coming weekend (7-8 June 2019) my SPROG 3 suddenly developed an intermittent faults and kept dropping power to the […]

A nice review of Die Keinnamebahn at Narrow Gauge North 2019

009 News, the members’ magazine of the 009 Society, published this lovely comment on Die Keinnamebahn at its showing at Narrow Gauge North 2019 in April at Pudsey. SWMBO and I are, as we say up North, “well chuffed”! Die Keinnamebahn will next be on display at the Chesterfield Model Railway Society’s show at Bakewell, […]

Vandals destroy years of work and thousands of pounds of models at model railway exhibition.

I could not believe the venality and sheer evil of the ‘youths’ who broke into the school at Welland Academy in Stamford, Lincolnshire, on Saturday 18th May 2019, where the Market Deeping Model Railway Club were holding their annual model railway exhibition. In a matter of minutes four ‘feral’ teenagers, who at 3am were away […]

ESU Loksound DCC sound decoder programming/mapping service in UK

I can offer a ESU Loksound sound programming/mapping service to customers in the U.K. at an economical rate. I am able to program ESU decoders from V2 to V5 (but not the Loksound Select Direct decoders as these are not reprogrammable with a new soundscape). I can program any of the locomotive sound profiles available for download […]

New Roco 2095 OBB H0e scale locomotive with factory fitted sound

I recently bought a ‘surplus to requirements’ model of the Class 2095 narrow gauge diesel locomotive as used on the ÖBB line, amongst others, from a member of the Narrow Gauge Railway Modellers Online forum (www.ngrm-online.co.uk). This was an impulse buy, but the price asked and the wow-factor and reviews of this loco were irresistible. […]

Using DCC Concepts twin wire signals with the Train-Tech SC1 3-wire DCC signal decoders

I wanted to use some DCC Concepts 2-aspect ground signals that I had bought. They came with two DCC Concepts Alpha Mimic LED controllers but at 50 UKP each, and capable of operating 24 LEDs each, they are too expensive to use on Die Keinnamebahn where only a few signals are on each board and […]

Using foamcore board to make a stockbox in a Ryman 4 litre plastic box with lid

I decided that it was taking too long to unpack and pack my rolling stock at exhibitions by having to use the manufacturers packaging. I have therefore started to make stock boxes by adding an inner liner of foamcore board with partitions to keep the stock safe. Ryman, in the U.K., sell various sizes of […]

We use laser cut MDF baseboards by Tim Horn

I made my H0e exhibition layout “Die Keinnamebahn” using the laser cut MDF scenic baseboards manufactured by Tim Horn (https://timhorn.co.uk). Tim’s original 400x250x50 mm scenic baseboards were made using 3mm MDF but his new style boards now use 6mm thick moisture resistant MDF with 3mm ordinary MDF sides and ends. The ends are accurately cut […]

Don’t expect this Aldi alarm padlock to protect your model railway shed

The Aldi Alarm Padlock is, in my opinion, a total waste of money. Publicised by Aldi as suitable for protecting your shed or garage it has a fatal flaw, one night of rain destroys the electronic alarm circuitry! The padlock has upward facing loudspeaker holes which have no effective sealing. One night of rain filled […]

The new Aldi folding box truck is perfect as a stock box carrier using Rymans 4 litre plastic boxes.

I will be using the 4 litre plastic storage boxes from Rymans to hold my unboxed rolling stock that I will be taking to the exhibitions I will be attending with my H0e Narrow Gauge exhibition layout Die Keinnamebahn. I will fit out the storage boxes with foam board partitions to protect the stock. To […]

An amazing layout at Model Train Expo Ontraxs! 2019

This layout, De Graafstroom by Vincent de Bode, was filmed by Ted Polet at the Model Train Expo, Ontraxs! 2019 at the Dutch Railway Museum (Het Spoorwemuseum) Utrecht, 15/16/17 March 2019. Watch the beautiful scene develop as the swan floats down the river and the sailing barge slowly heads up river to pass under the […]

Hide your SSID when using WiFi control at exhibitions

I have been developing a JMRI (Java Model Railway Interface) DCC (Digital Command Control) system for my exhibition layout “Die Keinnamebahn” that uses mobile smart phones as WiFi connected hand throttles connected to the JMRI software running on a Raspberry Pi Model 3B+ microcomputer set up as a WiFi access point. I got the […]

New signalling on Die Keinnamebahn

With Narrow Gauge North at Pudsey fast approaching on Saturday 9th March I decided to add some signalling to Die Keinnamebahn. To this end the first light I fitted is to protect the coaling station crossover. I fitted a Viessmann 4011 stop signal and used a Train-Tech SC1 DCC signal light controller to automatically change […]

The ‘Harzkamel’ on Die Keinnamebahn

A short video of my Brawa br199 ‘Harzkamel’ running on Die Keinnamebahn at the NMDRM exhibition at Chapel-en-le-Frith on 23/24 February 2019

A ‘new’ Harzkamel beast for Die Keinnamebahn

Ever since I saw this loco by Brawa in the modelling press several years I have wanted one. This H0e or H0m gauge model (wheelsets for both 9mm and 12mm versions are provided) of the massive BR 199 locomotive used in the Harz region of northern Germany. The massive shape gave it the nickname “Harzkamel”. My […]

Using an uninterruptible power supply (UPS) on your model railway

Because we will be using a computerised, Raspberry Pi based, DCC control system with wireless hand controllers to control Die Keinnamebahn at exhibitions I wanted to protect the system from induced spikes or drop outs in the mains electricity supply. Dropouts can occur if someone accidentally, or inadvertently, unplugs a mains supply lead to the layout […]

Track problems on Die Keinnamebahn and how to painlessly fit fishplates

Two weeks to go to my first exhibition of 2019 at Chapel-en-le-Frith on 23/24 February and I am testing Die Keinnamebahn, my H0e exhibition layout. The point at the station throat was not polarising the frog properly and so I changed the Seep PM4 switching latched solenoid point motor. Testing showed it was now OK […]

Running JMRI on a Raspberry Pi fitted into a VESA mounting case

As we progress getting ready for the first of our 2019 exhibitions at Chapel-en-le-Frith I have now fitted the Raspberry Pi microcomputer into a £10 fan cooled case that fits onto the back of the TV and connects to the DVI video connection on the TV. The case, complete with fan and all fitting screws, […]

Getting Die Keinnamebahn ready for our 2019 exhibitions.

Well, it is another year gone by and I have taken Die Keinnamebahn out of its storage crates to test it, and fix any problems on it, so that it can show at the first of this year’s exhibitions, Chapel-en-le Frith on 23/24 February. Last year we had a minor problem with the track lifting at a […]

An inexpensive adjustable strip cutter

it never ceases to amaze me what you can buy via a certain internet auction site. For £4.42 inclusive of postage you get a brass handled precision cutter with easily replaceable snap-off blades for less than you would expect to pay for a flimsy plastic component. Sold as a “Leather Craft Tools DIY Incision Cutter […]

Die Keinnamebahn mugs for exhibitions

As a little whimsy I designed, and had made, some mugs for myself and my wife for use at exhibitions. They are aluminium heat retaining travel mugs with sealed lids. Labelled “Zugfürer” (Driver) and “Zugwache” (Guard) they, along with our banner and custom Die Keinnamebahn sweatshirts will, hopefully, add a little extra professionalism to our […]