When laying track on a curve using copper clad sleepers or onto copper clad sheet for embedded track the track needs to be eased in gauge slightly for good running. To do this on Peco Code 80 rail then you need a 3-point track gauge. I have been unable to find a commercially produced 3-point track gauge for code 80 rail and so I decided to try making my own.

When laying track on a curve using copper clad sleepers or onto copper clad sheet for embedded track the track needs to be eased in gauge slightly for good running. To do this on Peco Code 80 rail then you need a 3-point track gauge. I have been unable to find a commercially produced 3-point track gauge for code 80 rail and so I decided to try making my own.

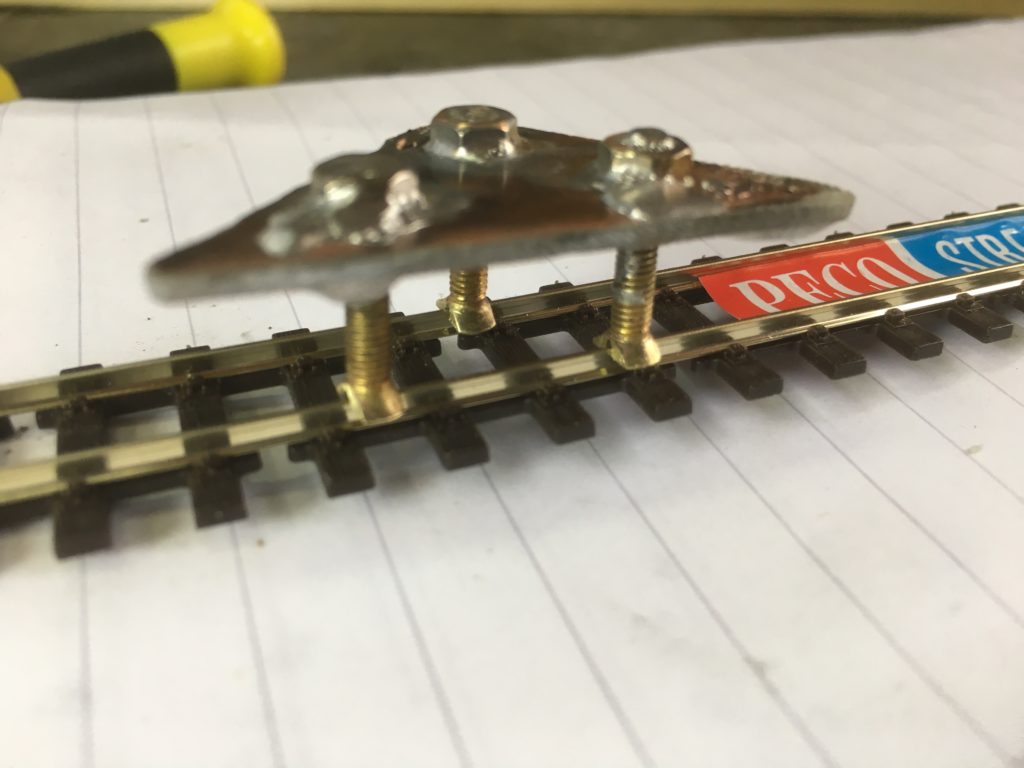

I used some double-sided copper coated glass fibre PCB board. I first drilled out the single point of the gauge to take a 3mm brass countersunk screw which was clamped in place using 2 nuts. The slot in the screw head was almost perfect fit for Code 80 rail. I then determined the correct width of the track and drilled out 2 more holes exactly at the track gauge from the single screw and double the track width (I.e. 9.0×2=18mm) apart. Two more 3mm screws were added to the board with nuts either side.

I clipped the slots of the screws onto a piece of Peco 009 track and then soldered the nuts and screws to the copper back of the PCB. I then turned the board over and did the same for the underside nuts etc.

The screw heads were cut back on the sides to make the gauge heads that were in contact with the rail only about 2mm wide.

The screw heads were then gently bent with pliers to be an exact fit to a straight section of Peco 009 track.

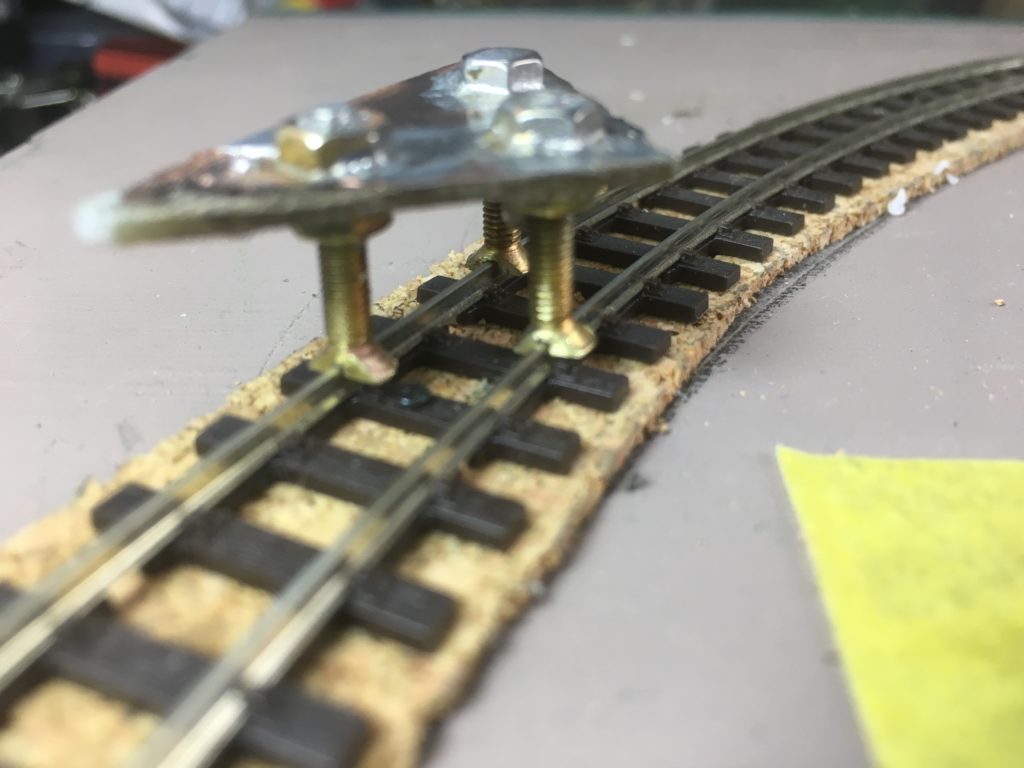

You can see how it works below.

To pre-bend the rail I use the very nicely made Rail Track Rail Roller. It is not cheap, mine cost me about £50, but it does a good smooth bend.